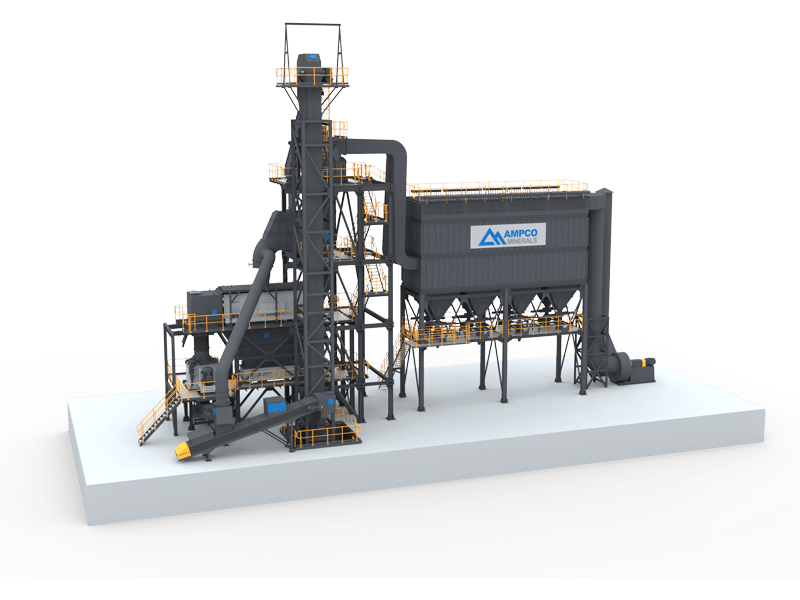

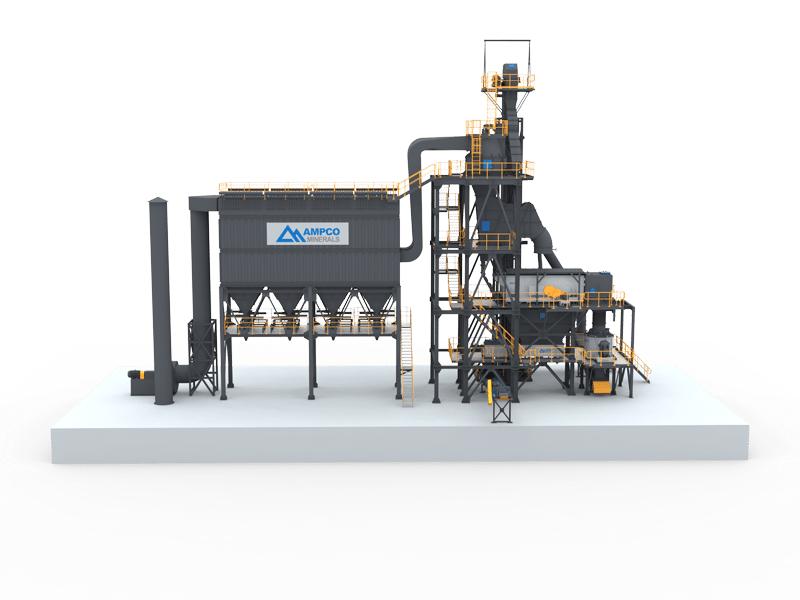

Traditional sand plants relied on clean, accessible water to produce high-grade sand. Our plants operate without water and can be situated near construction sites, aggregate quarries, or wherever they are needed to produce sand.

Stationary & Mobile Dry Sand PlantsGlobal Supplier & Manufacturer of Mineral Processing Solutions

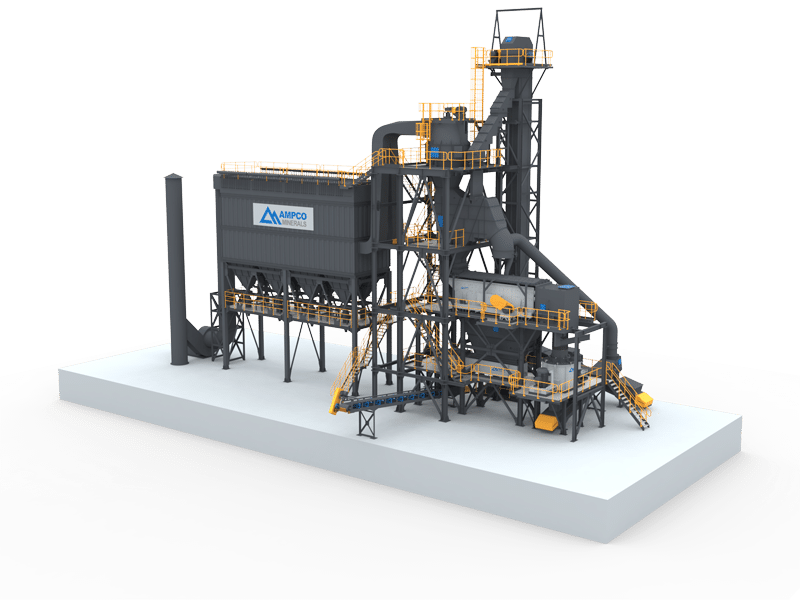

The Dry Sand Plant is a sustainable option for producing high-quality sand with ideal particle shape and grading for your projects. Explore the benefits of this innovative and highly productive plant.

An Environmentally Sustainable Option

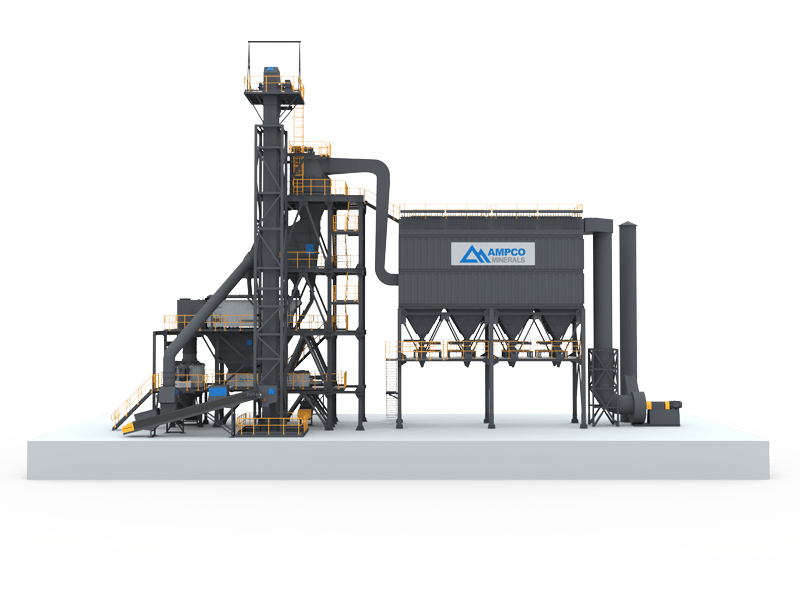

Due to the increasing demand for sand in concrete construction for global infrastructure projects, the search for native sand is becoming more challenging. Our dry sand plants provide the flexibility to process a variety of aggregates based on your specific concrete construction needs.

A fully enclosed plant design with negative intake pressure eliminates dust emissions. The fine dust particles collected are either stockpiled onsite or sold at a high value for other uses.

An automated central control system monitors the plant and can be controlled remotely from a computer or smartphone to ensure consistent operations.

No ponds or chemicals are needed to treat wastewater, dispose of sludge, or manage waste and wastewater from traditional sand manufacturing plants. This reduces site equipment wear, transportation, and handling costs.

The Dry Sand Plant can be used for on-site concrete waste recycling to reduce transportation and disposal costs and produce sand.

Projects & Services

Ready to revolutionize your site’s production? Our solutions can optimize your plant layout, minimize downtime, and maximize efficiency. Let us help you achieve peak performance.